Products

Everything from a single source for the processing industry.

tool & mold

making.

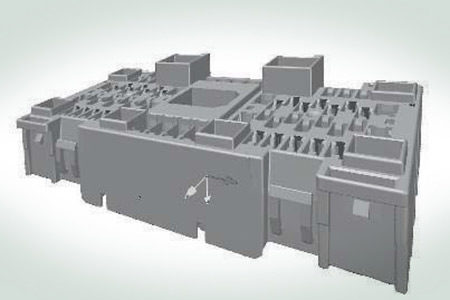

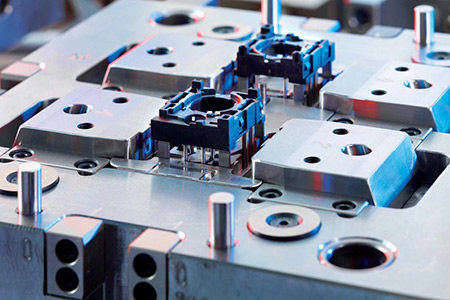

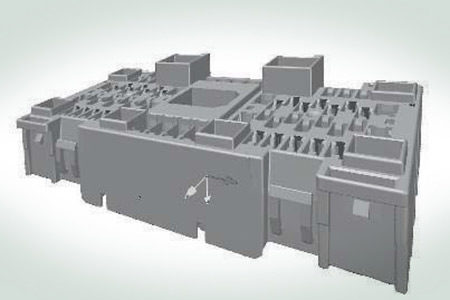

We are your partner for prototype and series tools throughout the entire development and creation phase. Our services cover the entire value chain from technical consulting, conception and design to 3D prototype construction and the prototype tool for manufacturing the first components from original material through to the series tool with optimized cooling and innovative temperature control technology.

We use an extremely wide range of manufacturing methods to produce prototypes and small-scale series based on customer requirements. Our methods range from conventional prototype mould construction to vacuum-casting and RIM methods, as well as all standard additive manufacturing methods. Every day counts when it comes to the production of prototypes.

We guarantee:

- Quick prototype production from individual component to assembly (ASSY)

- Use of state-of-the-art CAD systems including 3D visualisation

- Measurement of components on 3D measuring machines

- Comprehensive analysis options for mould filling, distortion, cooling times, etc.

- Maximum flexibility and reliability

- Discretion and data security for your developments

Conventional prototype moulds

We develop solutions for challenging tasks, and provide you with comprehensive advice during the entire design and development phase. With state-of-the-art CAD systems, we are right on hand to assist you with 2D and 3D visualisations of the project, from the very first draft right through to series readiness. We work with you to create components that meet your requirements with extremely short delivery times.

As a system partner, we offer:

- Manufacturing, close-to-production components in original material or even entire assemblies made of different materials, including installation and measuring

- Comprehensive analysis options for mould filling, distortion, cooling times, etc.

Vacuum casting

The vacuum-casting method is a quick and cost-effective way of producing initial components using flexible silicone moulds. Unlike printed injection moulds, it is not possible to use original material; only comparable materials can be used.

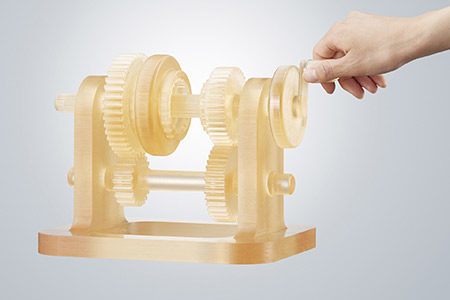

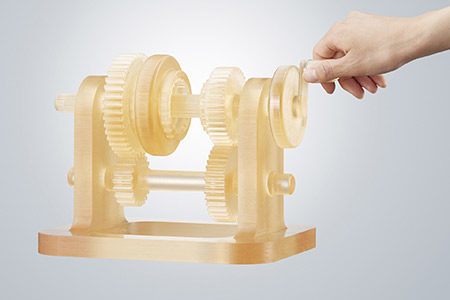

Additive manufacturing of prototypes

Additive manufacturing methods can be the most sensible solution for the quick production of initial prototypes. enesty additiv is able to offer a high level of expertise in this area based on its many years of experience in R&D projects and case studies.

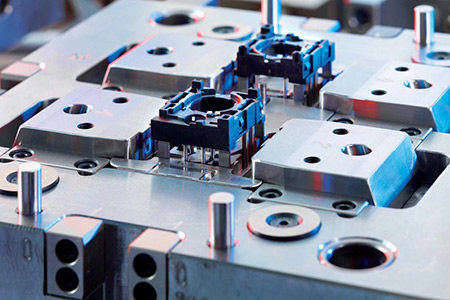

We are your trusted partner for premium-quality series injection moulds that provide optimal value for money. This is possible thanks to our collaboration with partners in Germany, Spain and China.

With our support, you can make the most of the benefits of global sourcing. We are on hand to assist you throughout the entire production process based on our experience in series production and our enesty temperature control system 4.0®.

Our shared goal is to optimise your production.

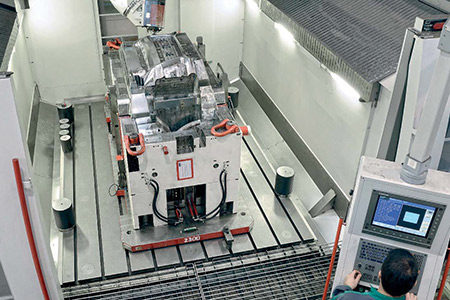

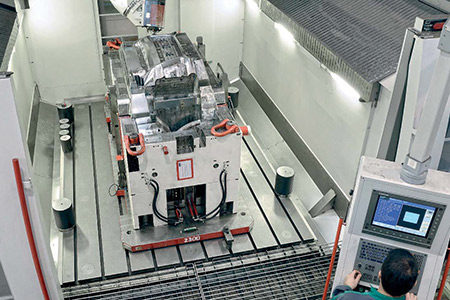

Series moulds from Germany

Our product range covers the development, production, servicing and maintenance of tools and moulds for the machining and processing of plastics (Duroplast and Thermoplast) and components in the area of plastics and metal processing.

We work in close collaboration with powerful, renowned partners from the region. This allows us to respond to your requirements and implement processes quickly and flexibly.

Our range of services includes:

- Mould conception and design

- Production and final assembly

- Mould trialling capacities up to 1300 t clamping force

- Maintenance, repair and modification work

Technical equipment:

- CAD design

- CNC/HSC milling

- Wire-cutting and die-sink EDM

- Start-hole EDM

- Measurement in our in-house measuring centre

- CNC turning

Series moulds from Spain

Our partner is HISPAMOLDES s.a. As an exclusive representative, we provide services relating to the design, production, maintenance and servicing of injection moulds with a total weight of up to 50 t. Our specialist engineers oversee projects on site at your premises in either German or English.

Moulds for:

- Front ends

- Bumpers

- A/B/C pillars

- Installation supports

- Dashboards

- Components that can be produced using 1-component, 2-component and 3-component methods

Quality assurance:

- Eleven 3-axis CNC machining centres

- One 6-axis CNC deep drilling machine

- Five conventional drilling machines

- Two lathes

- Three grinding machines

- Two wire-cutting EDM machines

- Five die-sink EDM machines

- Three spotting presses

Series moulds from China

We specialise in the import of high-quality injection moulds from China, and our German- and English-speaking project management team is on hand to support you in your project from the initial enquiry right through to the delivery of the mould. Our portfolio includes prototype moulds with an output quantity of up to 20,000 cycles in non-cured mould design, as well as small-batch series moulds with 25,000 cycles and more with cured series moulds. We can of course carry out mould trials on your parts with clamping forces of 30 t to 3200 t. All moulds are produced in line with your specifications and are fitted with the required mould systems.

Mould maintenance, as well as warranty and change management, are performed by leading German or European companies.

Benefits of global sourcing:

- Taking advantage of differences in economies, growth and currency

- Reducing dependencies

- Benefiting from the specialisations of individual regions and providers

your contact for tool & mold making

temperature

control.

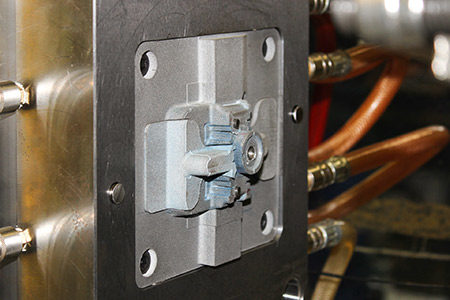

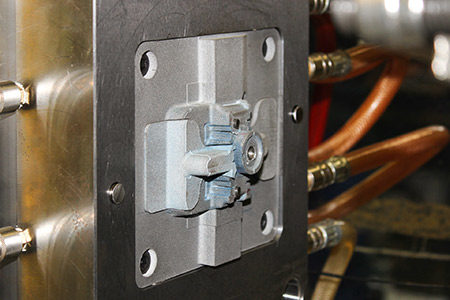

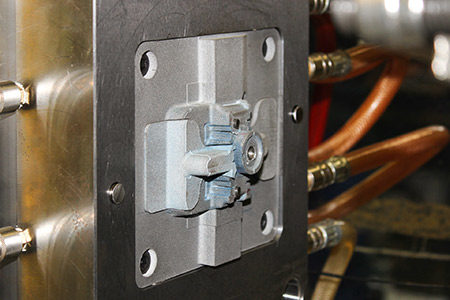

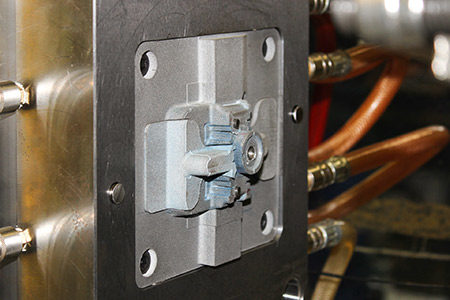

Discover the future of temperature control. Our temperature control systems from orcinus meet the growing demands of modern spray shops for process control and data acquisition. With orca, we provide maintenance-free temperature control and, with the non-contact measuring principle of water or oil, offer high process reliability, simple operation and optimum volume flow design. In addition to orca, we also offer our compact smartshark systems under the “orcinus” brand. In combination with the temperature control units of our partners, we ensure greater safety throughout your entire production process.

Process reliability and efficiency in temperature control.

Our high-performance temperature control units are the “powerful engine” of our system. Experience the highest quality for industrial applications up to 180°C. We have put together a selection of three possible relevant temperature control units for you. If you are interested in other temperature control units, please feel free to contact us.

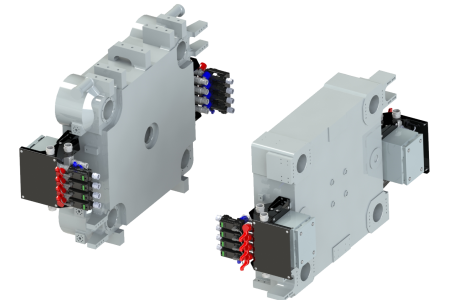

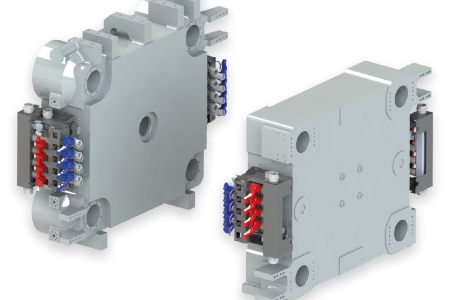

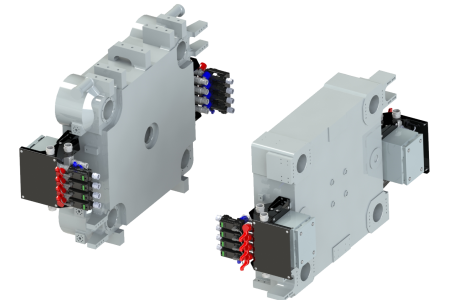

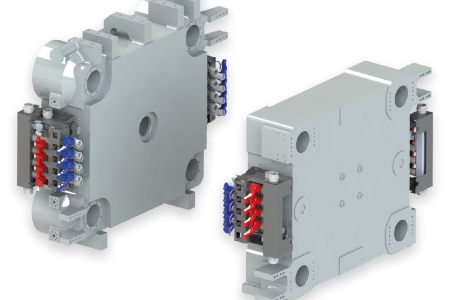

orcinus

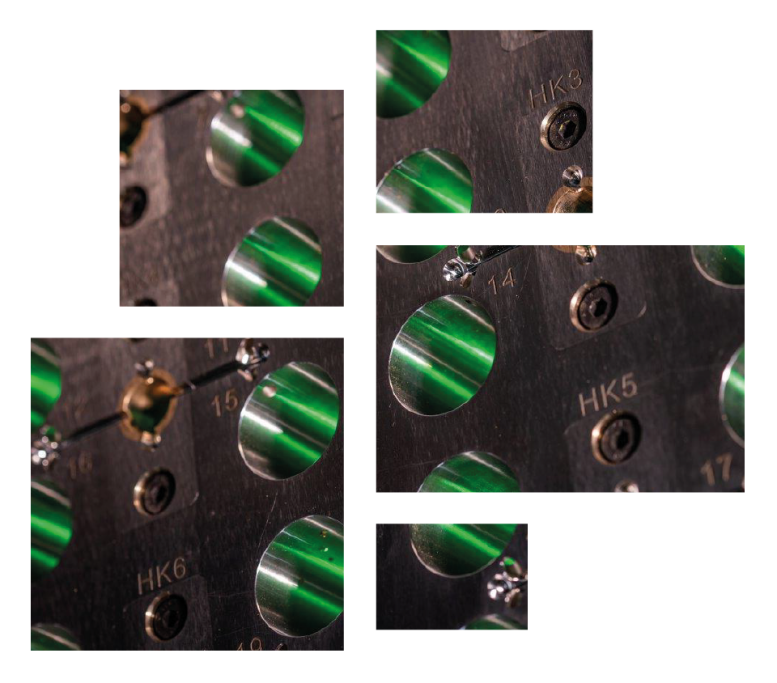

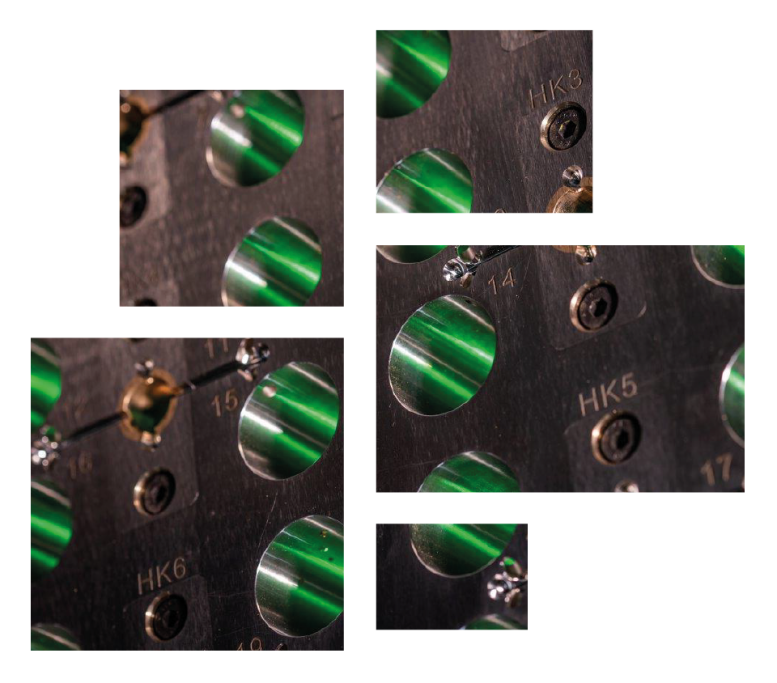

The heart of this system is a double ultrasonic sensor that can measure the temperatures of water and oil up to 180 degrees without contact. orca offers you the option of optimizing your process with 2-144 circuits and is also maintenance-free. It is divided into distributor blocks with 2, 4, 6, 8, 10 or 12 circuits. We install orca with a maximum of 20 blocks on your mold and thus reduce important cycle times. The orca system is based on the principle of parallel distribution. The control, distribution block and sensor components are optimally matched to the application in the manufacturing industry.

smartshark.

Our smartshark scores with its compact design. Optimize your process and save important cycle time – the system monitors your temperatures and flow rates. We also focus on high quality and fair prices. Save not only on your purchase, but also during production – smartshark is price-efficient. The system gives you the opportunity to optimize your process with 2-8 circuits per block. We install smartshark with a maximum of 20 blocks on your tool to ensure maximum process reliability.

A plus in performance.

orcinus and smartshark as an adjustable plus variant

A proportional valve in the flow controls the flow rate to ensure optimum temperature control performance. The flow rate is measured in the same way as with the standard systems.

Features compared to the orcinus and smartshark

- valve in the volume flow

- control of the desired flow rate setpoint per circuit possible (depending on the physical limits and the upstream system technology)

- compensation of pressure fluctuations in the overall system

- extremely robust valve system, which was developed for industrial water systems and is used in large quantities

- temperature measurement as on the orcinus (120 or 160 °C) and smartshark (100 °C)

- 1 valve per circuit

your contact for orcinus temperature control systems

additive manufacturing.

Freedom of design meets cost-effectiveness. We are your experts for additive manufacturing and turn your ideas into commercial success. With many years of experience in R&D projects, we offer tailor-made solutions, from customer-oriented component development to rapid cost estimation. Our know-how guarantees precise implementation and application-optimized components.

We support you along the entire process chain – from training and advice through to design support and ultimately to implementation in the production process.

We offer:

- Seminars and training sessions

- Design support and review

- New design or re-design of existing components

- Function optimisation

- Evaluation of potential of components/assemblies

- Cost estimate

- Component digitalisation

- Support with production preparation and implementation

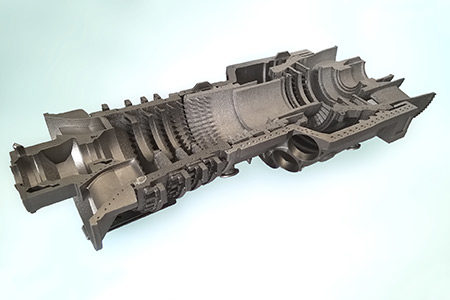

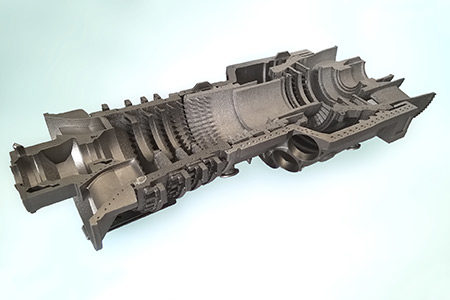

We produce components made from various materials using all standard additive manufacturing methods. Additive manufacturing is a profitable alternative particularly in the case of components with small batch sizes, a high level of complexity or quick delivery times.

Examples of standard methods:

- Plastic: PJ, SLA, SLS, MJF, FDM – acrylic resin, PA-GF, PA12, PC, ABS, etc.

- Metal: SLM, EBM – Al & Ti alloys, stainless & tool steels, etc.

We are open to requests for additional materials and methods and for research projects, which, in the event of their application, we will professionally review to enable a suitable implementation.

With our range of services, we will find the optimal technology to bring your components into reality.

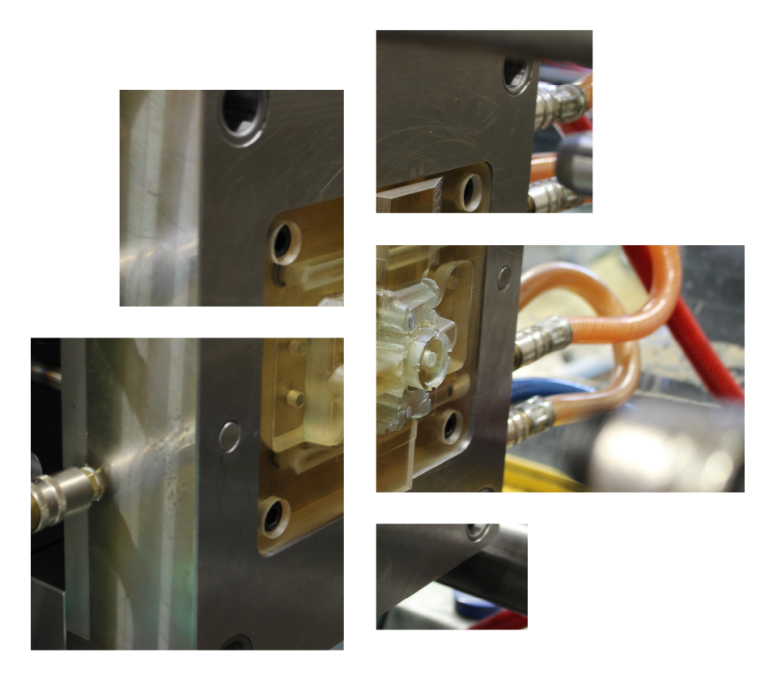

We recommend using the 3D printing method for production.

For the production of small-scale series in original material or series with very short cycle times, we recommend using the 3D printing method for production. This can achieve cost reductions and time savings of 50–80% in small-scale series production with prototype moulds.

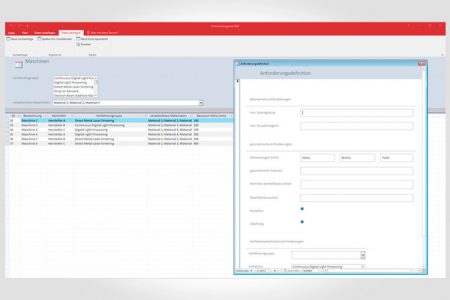

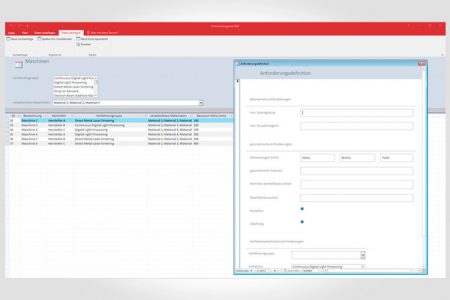

DigiToolAM – digital unterstützte Technologieauswahl im 3D-Druck

Anwender additiver Fertigung müssen bei der Wahl der für ihren Fall passenden Technologie zahlreiche Kriterien bezüglich Verfahren, Material und Gesamtprozess bewerten, um die richtige Entscheidung zu treffen. Mit dem DigiToolAM bietet enesty ein Werkzeug an, das die Technologiefindung deutlich vereinfacht. Die datenbankbasierte Lösung ist sowohl mit AM-spezifischem Wissen und Technologiekriterien als auch Kundenanforderungen „gefüttert“ und matcht mittels Suchalgorithmen zwischen Bedarf und passender Technologie. Der Beratungsprozess kann mit dem digitalen Werkzeug wesentlich verkürzt werden. Der Austausch nicht relevanter Informationen wird gespart. Dieses Vorgehen reduziert außerdem die Kosten für die Technologiefindung.

your contact for additive manufacturing

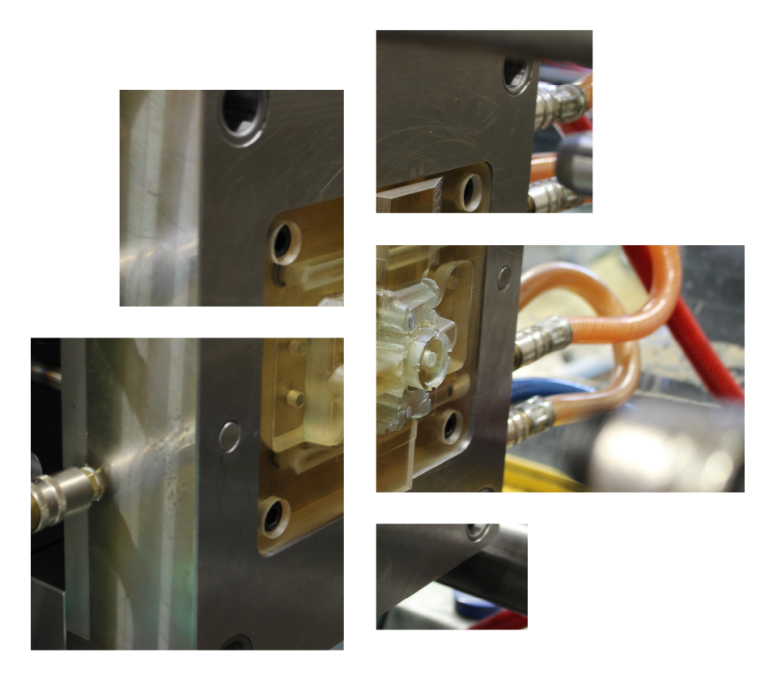

close contour

cooling.

We are your partner for efficient processes and high-quality components thanks to innovative close contour cooling. Our conesty tools eliminate additional machining work and enable significant quality improvements as well as 25-30% shorter cycle times for technical components.

your contact for close contour cooling

Produkte

Todo desde un mismo proveedor para la industria transformadora.

Fabricación de herramientas y moldes

fabricación de moldes.

Somos su socio para moldes prototipo y de serie durante toda la fase de desarrollo y creación. Nuestros servicios abarcan toda la cadena de valor, desde el asesoramiento técnico, la concepción y el diseño hasta la construcción de prototipos en 3D y la herramienta prototipo para la fabricación de los primeros componentes a partir del material original, pasando por la herramienta de serie con refrigeración optimizada e innovadora tecnología de control de la temperatura.

We use an extremely wide range of manufacturing methods to produce prototypes and small-scale series based on customer requirements. Our methods range from conventional prototype mould construction to vacuum-casting and RIM methods, as well as all standard additive manufacturing methods. Every day counts when it comes to the production of prototypes.

We guarantee:

- Quick prototype production from individual component to assembly (ASSY)

- Use of state-of-the-art CAD systems including 3D visualisation

- Measurement of components on 3D measuring machines

- Comprehensive analysis options for mould filling, distortion, cooling times, etc.

- Maximum flexibility and reliability

- Discretion and data security for your developments

Conventional prototype moulds

We develop solutions for challenging tasks, and provide you with comprehensive advice during the entire design and development phase. With state-of-the-art CAD systems, we are right on hand to assist you with 2D and 3D visualisations of the project, from the very first draft right through to series readiness. We work with you to create components that meet your requirements with extremely short delivery times.

As a system partner, we offer:

- Manufacturing, close-to-production components in original material or even entire assemblies made of different materials, including installation and measuring

- Comprehensive analysis options for mould filling, distortion, cooling times, etc.

Vacuum casting

The vacuum-casting method is a quick and cost-effective way of producing initial components using flexible silicone moulds. Unlike printed injection moulds, it is not possible to use original material; only comparable materials can be used.

Additive manufacturing of prototypes

Additive manufacturing methods can be the most sensible solution for the quick production of initial prototypes. enesty additiv is able to offer a high level of expertise in this area based on its many years of experience in R&D projects and case studies.

We are your trusted partner for premium-quality series injection moulds that provide optimal value for money. This is possible thanks to our collaboration with partners in Germany, Spain and China.

With our support, you can make the most of the benefits of global sourcing. We are on hand to assist you throughout the entire production process based on our experience in series production and our enesty temperature control system 4.0®.

Our shared goal is to optimise your production.

Series moulds from Germany

Our product range covers the development, production, servicing and maintenance of tools and moulds for the machining and processing of plastics (Duroplast and Thermoplast) and components in the area of plastics and metal processing.

We work in close collaboration with powerful, renowned partners from the region. This allows us to respond to your requirements and implement processes quickly and flexibly.

Our range of services includes:

- Mould conception and design

- Production and final assembly

- Mould trialling capacities up to 1300 t clamping force

- Maintenance, repair and modification work

Technical equipment:

- CAD design

- CNC/HSC milling

- Wire-cutting and die-sink EDM

- Start-hole EDM

- Measurement in our in-house measuring centre

- CNC turning

Series moulds from Spain

Our partner is HISPAMOLDES s.a. As an exclusive representative, we provide services relating to the design, production, maintenance and servicing of injection moulds with a total weight of up to 50 t. Our specialist engineers oversee projects on site at your premises in either German or English.

Moulds for:

- Front ends

- Bumpers

- A/B/C pillars

- Installation supports

- Dashboards

- Components that can be produced using 1-component, 2-component and 3-component methods

Quality assurance:

- Eleven 3-axis CNC machining centres

- One 6-axis CNC deep drilling machine

- Five conventional drilling machines

- Two lathes

- Three grinding machines

- Two wire-cutting EDM machines

- Five die-sink EDM machines

- Three spotting presses

Series moulds from China

We specialise in the import of high-quality injection moulds from China, and our German- and English-speaking project management team is on hand to support you in your project from the initial enquiry right through to the delivery of the mould. Our portfolio includes prototype moulds with an output quantity of up to 20,000 cycles in non-cured mould design, as well as small-batch series moulds with 25,000 cycles and more with cured series moulds. We can of course carry out mould trials on your parts with clamping forces of 30 t to 3200 t. All moulds are produced in line with your specifications and are fitted with the required mould systems.

Mould maintenance, as well as warranty and change management, are performed by leading German or European companies.

Benefits of global sourcing:

- Taking advantage of differences in economies, growth and currency

- Reducing dependencies

- Benefiting from the specialisations of individual regions and providers

su contacto para moldes de inyección

Alejandro Ávila Jiménez

director general de sais enesty de méxico

Tel +34 630 926 191

Mail saismexico@enesty.org

control de

temperatura.

Descubra el futuro del control de temperatura. Nuestros sistemas de control de temperatura de orcinus satisfacen las crecientes demandas de los talleres de pulverización modernos en cuanto a control de procesos y adquisición de datos. Con orca, proporcionamos un control de la temperatura que no requiere mantenimiento y ofrecemos una alta fiabilidad del proceso, un funcionamiento sencillo y un diseño optimizado del flujo volumétrico gracias al principio de medición sin contacto del agua o el aceite. Además de orca, también ofrecemos nuestros sistemas compactos smartshark bajo la marca “orcinus”. En combinación con las unidades de control de temperatura de nuestros socios, garantizamos una mayor seguridad en todo su proceso de producción.

Process reliability and efficiency in temperature control.

Our high-performance temperature control units are the “powerful engine” of our system. Experience the highest quality for industrial applications up to 180°C. We have put together a selection of three possible relevant temperature control units for you. If you are interested in other temperature control units, please feel free to contact us.

orcinus

The heart of this system is a double ultrasonic sensor that can measure the temperatures of water and oil up to 180 degrees without contact. orca offers you the option of optimizing your process with 2-144 circuits and is also maintenance-free. It is divided into distributor blocks with 2, 4, 6, 8, 10 or 12 circuits. We install orca with a maximum of 20 blocks on your mold and thus reduce important cycle times. The orca system is based on the principle of parallel distribution. The control, distribution block and sensor components are optimally matched to the application in the manufacturing industry.

smartshark.

Our smartshark scores with its compact design. Optimize your process and save important cycle time – the system monitors your temperatures and flow rates. We also focus on high quality and fair prices. Save not only on your purchase, but also during production – smartshark is price-efficient. The system gives you the opportunity to optimize your process with 2-8 circuits per block. We install smartshark with a maximum of 20 blocks on your tool to ensure maximum process reliability.

A plus in performance.

orcinus and smartshark as an adjustable plus variant

A proportional valve in the flow controls the flow rate to ensure optimum temperature control performance. The flow rate is measured in the same way as with the standard systems.

Features compared to the orcinus and smartshark

- valve in the volume flow

- control of the desired flow rate setpoint per circuit possible (depending on the physical limits and the upstream system technology)

- compensation of pressure fluctuations in the overall system

- extremely robust valve system, which was developed for industrial water systems and is used in large quantities

- temperature measurement as on the orcinus (120 or 160 °C) and smartshark (100 °C)

- 1 valve per circuit

su contacto para los sistemas de control de temperatura orcinus

Alejandro Ávila Jiménez

director general de sais enesty de méxico

Tel +34 630 926 191

Mail saismexico@enesty.org

aditivo de fabricación.

La libertad de diseño se une a la rentabilidad. Somos sus expertos en fabricación aditiva y convertimos sus ideas en éxitos comerciales. Con muchos años de experiencia en proyectos de I+D, ofrecemos soluciones personalizadas, desde el desarrollo de componentes orientados al cliente hasta una rápida estimación de costes. Nuestros conocimientos técnicos garantizan una implementación precisa y componentes optimizados para la aplicación.

We support you along the entire process chain – from training and advice through to design support and ultimately to implementation in the production process.

We offer:

- Seminars and training sessions

- Design support and review

- New design or re-design of existing components

- Function optimisation

- Evaluation of potential of components/assemblies

- Cost estimate

- Component digitalisation

- Support with production preparation and implementation

We produce components made from various materials using all standard additive manufacturing methods. Additive manufacturing is a profitable alternative particularly in the case of components with small batch sizes, a high level of complexity or quick delivery times.

Examples of standard methods:

- Plastic: PJ, SLA, SLS, MJF, FDM – acrylic resin, PA-GF, PA12, PC, ABS, etc.

- Metal: SLM, EBM – Al & Ti alloys, stainless & tool steels, etc.

We are open to requests for additional materials and methods and for research projects, which, in the event of their application, we will professionally review to enable a suitable implementation.

With our range of services, we will find the optimal technology to bring your components into reality.

We recommend using the 3D printing method for production.

For the production of small-scale series in original material or series with very short cycle times, we recommend using the 3D printing method for production. This can achieve cost reductions and time savings of 50–80% in small-scale series production with prototype moulds.

DigiToolAM – digital unterstützte Technologieauswahl im 3D-Druck

Anwender additiver Fertigung müssen bei der Wahl der für ihren Fall passenden Technologie zahlreiche Kriterien bezüglich Verfahren, Material und Gesamtprozess bewerten, um die richtige Entscheidung zu treffen. Mit dem DigiToolAM bietet enesty ein Werkzeug an, das die Technologiefindung deutlich vereinfacht. Die datenbankbasierte Lösung ist sowohl mit AM-spezifischem Wissen und Technologiekriterien als auch Kundenanforderungen „gefüttert“ und matcht mittels Suchalgorithmen zwischen Bedarf und passender Technologie. Der Beratungsprozess kann mit dem digitalen Werkzeug wesentlich verkürzt werden. Der Austausch nicht relevanter Informationen wird gespart. Dieses Vorgehen reduziert außerdem die Kosten für die Technologiefindung.

su contacto para la fabricación aditiva

Alejandro Ávila Jiménez

director general de sais enesty de méxico

Tel +34 630 926 191

Mail saismexico@enesty.org

refrigeraciòn cercana al contorno.

Somos su socio para procesos eficientes y componentes de alta calidad gracias a la innovadora refrigeración conforme. Nuestros moldes conformados eliminan el trabajo de mecanizado adicional y permiten mejoras significativas de la calidad, así como tiempos de ciclo un 25-30% más cortos para componentes técnicos.

su contacto para herramientas conesty

Alejandro Ávila Jiménez

director general de sais enesty de méxico

Tel +34 630 926 191

Mail saismexico@enesty.org